CIMCO Software Suite

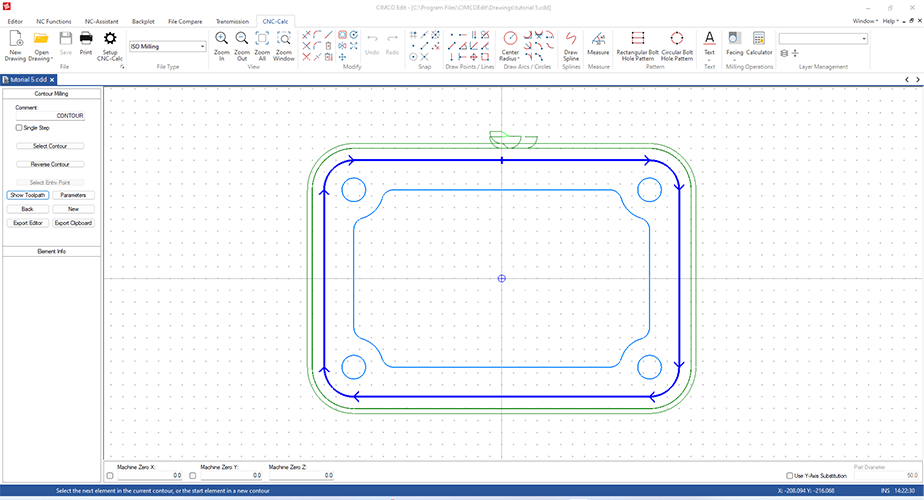

CNC-Calc

A simple CAD/CAM solution for the workshop

Draw 2D geometrical contours, create toolpaths for milling and turning machines, and generate NC code in minutes.

From simple to complex

CIMCO CNC-Calc is an add-on for CIMCO Edit that enables novice programmers a cost effective solution to draw 2D geometrical contours, lay out toolpaths for milling and turning, and simulate the resulting NC program.

The comprehensive set of available functions in CNC-Calc also makes it suitable for handling more complex geometrical drawings. Drawing functions include advanced trimming of elements, easy creation of fillets, full support for transformations, many options for snapping to elements, and easy creation of bolt hole patterns.

Benefits

Easy to use

CIMCO CNC-Calc is designed to be used by the operators and toolmakers who are untrained in advanced CAD/CAM systems.

Increase productivity

Get rid of calculators and trigonometric tables. CNC-Calc provides a simple interface and functionality to get work done faster.

Optimised toolpaths

Reduce machining time, improve surface quality, and minimise tool wear with optimised toolpaths for both milling and turning.

Prepare imported geometry

Import DXF files to prepare for editing and machining. Easily delete, move, duplicate, mirror elements and much more.

Validate NC code

Use the functionality in CIMCO Edit to view, edit, and simulate the generated toolpaths before running any code on your CNC machine.

Ideal for workshops

CNC-Calc is a helpful tool for daily NC programming tasks and an ideal choice for workshops that are new to CAD/CAM.

Features

Essential drawing tools

Draw contours using points, lines, arcs, and splines, and use transforms to move, rotate, scale, mirror, and offset elements.

Fillets and Chamfers

Create Fillets or Chamfers on corner intersections. Simply select a corner and specify a radius or an angle.

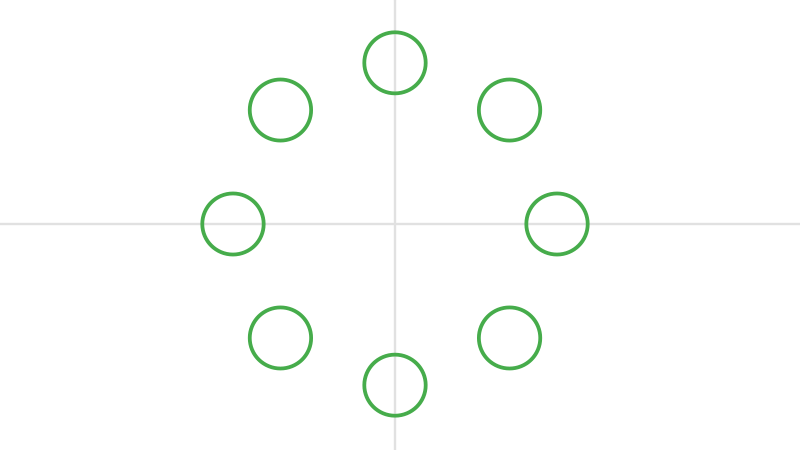

Bolt Hole patterns

Create rectangular (rows and columns) and circular (full circle or circle segment) bolt hole patterns in seconds.

Trim and Snap

Trim intersections with a few mouse-clicks and easily select elements with cursor snapping such as intersections, circles, and center points.

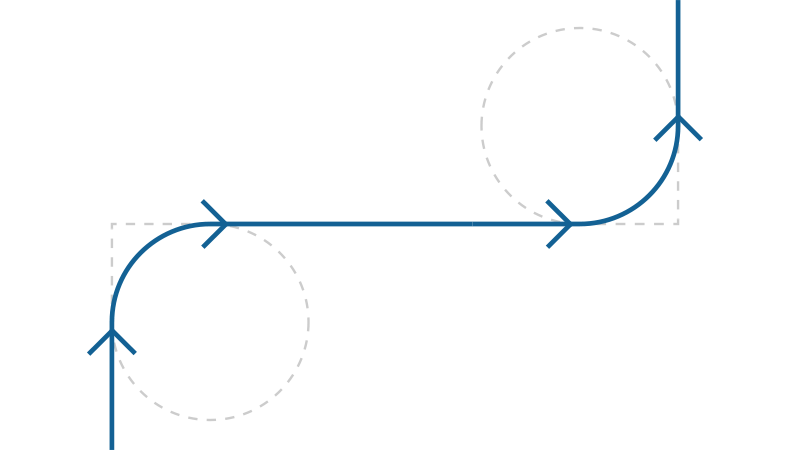

Milling and Turning operations

Lay out toolpath for milling or turning directly on your geometry using machining strategies such as Facing, Roughing, Contour, Constant Cut, Drilling and more.

Letter milling

Mill simple letters and numbers on your workpiece or use True-Type fonts for a custom look. Set depth, feed, speed, and clearance for the operation.

Import DXF drawings

Import DXF files (CAD data file format) and generate toolpaths for different types of CNC controllers, such as ISO, Fanuc and Heidenhain.

Cutter compensation

For adjusting the toolpath, CNC-Calc supports user-defined cutter compensation types such as Computer, Controller, Wear, and Reverse (Inverse) Wear.

Integrated with CIMCO Edit

CNC-Calc has its own tab in the interface, and it integrates with all the powerful features of CIMCO Edit, such as NC code editing and toolpath simulation.

ALL FEATURES

System components

Integrated add-on for CIMCO Edit

As a fully integrated add-on, running in its ovn tab, you can take advantage of all the powerful features in CIMCO Edit such as NC code editing and toolpath simulation.

Navigation and ordering of elements

Mouse functions

Use the mouse to select, drag and zoom elemenets for a fluid and intuitive workflow.

Zoom

Several options for zooming in/out, zoom selection and fit to window.

Layers

Group and organise related elements in your drawing. Layers can be reordered or merged as needed and their visibility toggled on or off.

Snap to points and elements

Cursor snapping makes ot easy to select specific elements in your drawing such as intersections, circles, and center points.

Grid and Origin

Display a grid in the background of your drawing to help you align and measure objects. Adjust grid size and sub-grids to suit your needs. You can also show the origin and the X and Y axis lines to orient yourself in the drawing space.

Drawing and geometry

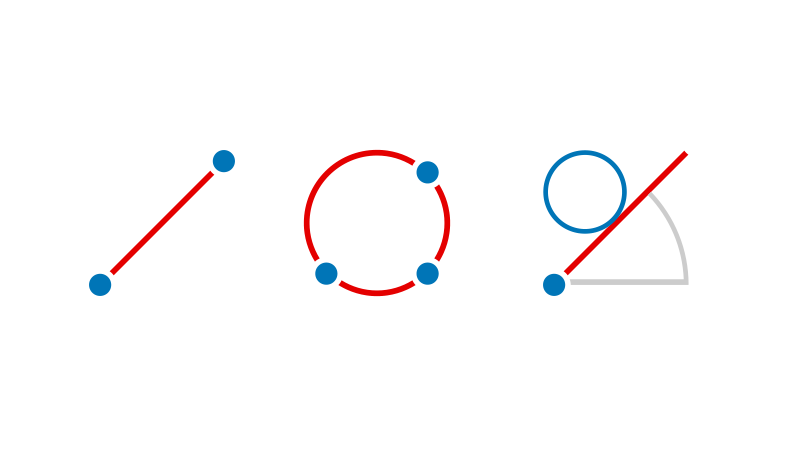

Drawing tools for points, lines, arcs, and splines

Draw 2D geometrical contours with points, lines, arcs, and splines. Advanced options include lines for Polar, Perpendicular, Parallel, Bisector, Tangents, and more.

Transformations

Move, rotate, scale, mirror, and offset elements.

Corner Fillets

Create Fillets on corner intersections. Simply select a corner and specify a radius.

Corner Chamfers

Create Fillets on corner intersections. Simply select a corner and specify an angle.

Rectangular Bolt Hole patterns

Duplicate Bolt Holes along a rectangular pattern defined by rows and columns.

Circular Bolt Hole patterns

Duplicate Bolt Holes along a circular pattern defined by either a full circle or a circle segment.

Trimming options

Several options for trimming intersecting geometry.

Break and Join Elements

Break an element into two pieces or join two selected elements into one.

Auto-remove Duplicates

Automatically delete duplicated elements in the drawing.

Useful Tools

Measure

Place measurements on a drawing.

Feed and Speed calculator

Can be used to generate tool changes, or to simply calculate the feed and speed, based on the data of a specific tool.

Strategies for milling and turning

Milling operations for Facing, Contour, Pocket, Constant Cut, and more.

- Facing

- Contour

- Constant Cut Inside Out

- Constant Cut Ouside In

- Drilling

- Helix Drilling

- Thread Milling

- Letter milling

Turning operations for Facing, Roughing, Finishing, Grooving, and more.

- Constant Cut Turning

- Roughing

- Facing

- Finishing

- Grooving

- Threading (ID, OD)

- End Drilling

- Cutoff

Letter milling

CNC-Calc support both simple text and TrueType letters.

File formats, import and export

Import DXF drawings

Import DXF files (CAD data file format).

Export Contour

Export a selection on the drawing as a contour. For controllers that support smart canned cycles.

Advanced options and settings

Cutter compensation

For adjusting the toolpath, CNC-Calc supports user-defined cutter compensation types such as Computer, Controller, Wear, and Reverse (Inverse) Wear.

User-defined Post Processor

Specify a Post Processor that will be used to format the output of the CNC-Calc operations.

Diameter programming (turning)

Set whether the X-axis output is in diameter measurement or in radius measurement.

Spline Substitution Tolerance

Sets the tolerance used when splines are substituted by line segments.